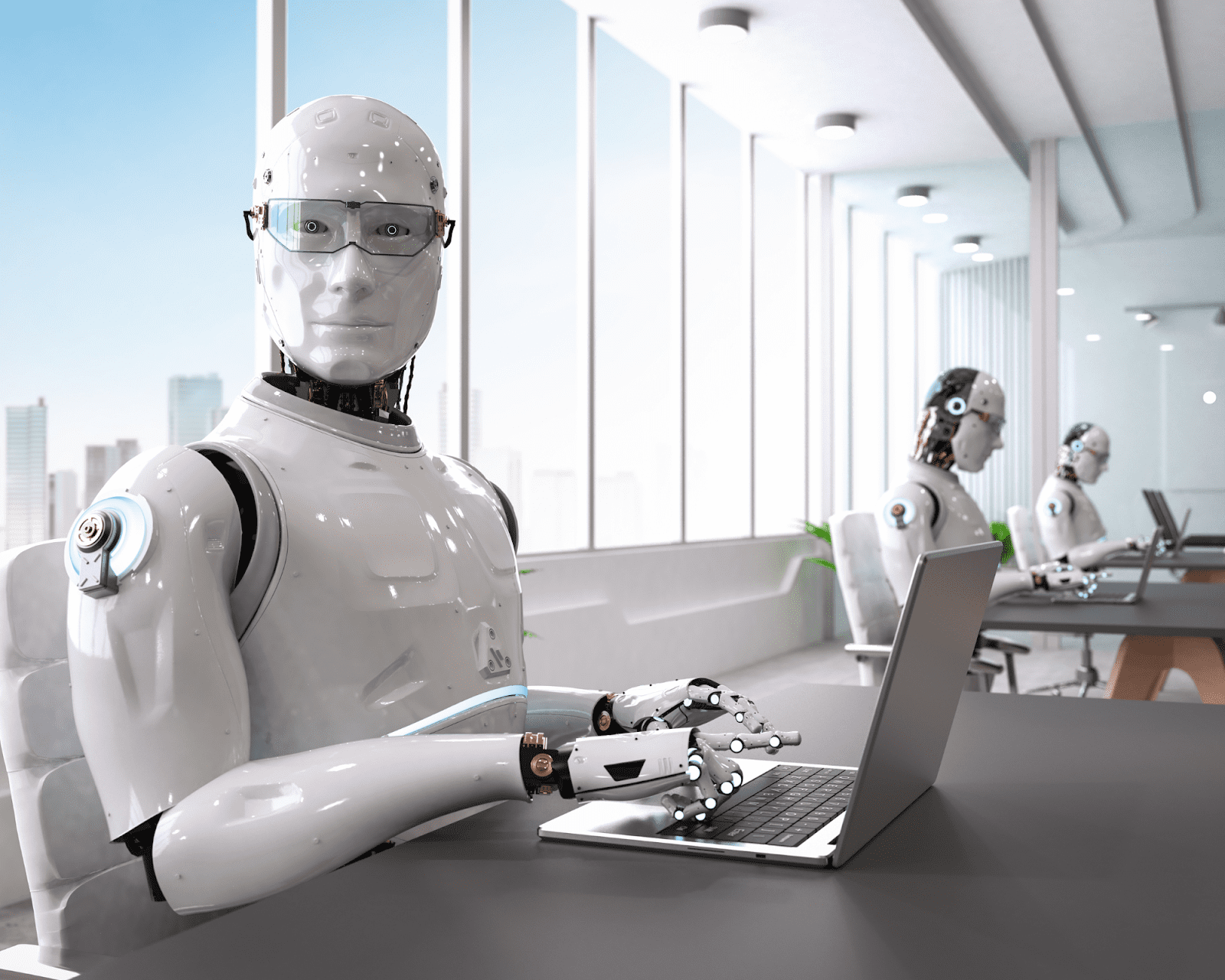

Automation in industry has changed the way companies produce, and the introduction of collaborative robots and artificial intelligence (AI) into production lines is one of the main reasons for this increase. These technologies are transforming the way companies produce, ensuring more efficiency and precision in the execution of tasks.

Collaborative robots are designed to work together with humans, without the need for security fences or physical barriers. They are programmed to perform specific tasks such as part assembly, welding, palletizing, packaging and quality inspection. They are able to work together with human workers, helping to increase production efficiency and reduce the risk of accidents.

AI, in turn, is a technology that allows machines to learn and perform tasks autonomously. With the help of algorithms and data analysis, AI systems are able to identify patterns, make predictions and make decisions based on collected information. In industry, AI can be used to optimize production processes, predict equipment failures, manage inventory, and even forecast consumer demand.

The combination of collaborative robots and AI can drive automation and efficiency in production. Collaborative robots can work together with AI systems, further increasing production efficiency. In addition, AI systems are able to analyze data collected by collaborative robots and identify opportunities for improvement in production.

One of the sectors that has most benefited from this combination of technologies is the automotive industry. Automakers have been using collaborative robots for parts assembly and AI systems for inventory management and demand forecasting. These technologies allow production to be more efficient and accurate, reducing production time and operating costs.

Another sector that has benefited from collaborative robots and AI is logistics. Collaborative robots can be used to move products within warehouses, while AI systems can optimize the transport route, reducing delivery time and transport costs. Additionally, AI can be used to forecast demand and prevent out-of-stocks, ensuring products are always available to customers.

Collaborative robot and AI technologies are also impacting the food and beverage industry. Collaborative robots can be used to package food and beverages, while AI systems can be used to ensure product quality by monitoring temperature and humidity levels during the production process. In addition, AI can be used to forecast demand and optimize food and beverage production, ensuring that products are always available to consumers.

Despite the benefits that collaborative robot and AI technologies bring to manufacturing, many people are concerned that automation could replace human jobs. However, collaborative robots are designed to work alongside human workers, not replace them. They can perform repetitive and dangerous tasks, allowing human workers to focus on more complex tasks like quality control and production management.

Furthermore, automation can create new jobs such as robotics engineers and AI specialists. These technologies can also increase the efficiency and productivity of companies, allowing them to grow and create more jobs.

Collaborative robots and AI are driving automation and efficiency in production. These technologies are transforming the way companies produce, ensuring more efficiency and precision in the execution of tasks. Despite fears that automation could replace human jobs, collaborative robots are designed to work alongside human workers, allowing them to focus on more complex tasks and creating new jobs.